Brakes

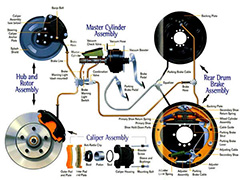

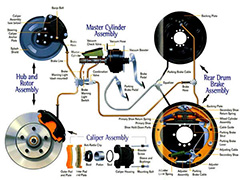

For most cars built after the late 70's you have more brake than car from the factory. Believe it or not most of those engineers actually know what they are doing! So saying it does seem to be a system on many vehicles that s very much neglected. Most people seem to think a "brake job" consists of slapping a new set of pads or shoes on and sending it down the road. Once in awhile a set of rotors or drums may need to be replaced and usually most people believe that that only happens after they hit metal to metal for a bit. Not true. The system was designed with a certain thickness brake drum or brake rotor in mind with a very specific finish applied to the metal that comes in contact with the brake material. When you stop a vehicle you are doing all sorts of things that if you remember your physics 101 classes has to do with converting kinetic energy into potential energy and the shifting a weight from one part of the vehicle to another and... But all you really need to know that when you step on the brake pedal and your car begins to shed energy and slow down you are creating heat, a lot of heat depending on speeds and how fast you are stopping. That heat needs to be shed or your brake rotor will fail or the brake shoes fall apart. As your brakes are applied the brake pad begins to absorb some of that heat and heat is transferred to the brake rotor or drum and spread out throughout the mass of the object and then out into the air - If the brake pads themselves or the rotors/drums are to thin they cannot dissipate the heat (energy) fast enough and will fail, could be noticed as a soft pedal or could be catastrophic as the pad or rotor come apart. As the heat builds up and is looking for a place to go it will go into the caliper or wheel cylinder and begin to boil your brake fluid as temperatures begin to pass 300, 500, or more degrees Fahrenheit. So it is more than just tossing out a set of pads that are too thin, is the rotor the correct thickness, is the finish on it still the correct one. Then all the moving parts need to be cleaned, a caliper that hangs just a little bit as it slides back because of a dirt build up will cause your brake pads to wear faster but it also creates heat and fluids begin to deteriorate as they are subjected too to high of temperatures for to long. Rotors fail and we are right back to where we were before you just ran into your neighbor. Brake fluid has a finite life - it absorbs moisture over time and becomes less capable of withstanding the high temperatures in today's brake systems. Hoses have a very finite life and usually fail from the inside out. One way is very simple, they block up and your brakes do not work on one side. Another is the core of the hose breaks down and will not contain the hundreds and in today's cars the thousands of pounds of pressure they are subjected to. Instead of 1500 pounds of force intended to apply your left front caliper 500 lbs. is sitting in the bulge on the side of the hose and your vehicle darts right and it takes more feet to stop. I can think of better places to save money on your vehicle than your brake system -

Brake tech I

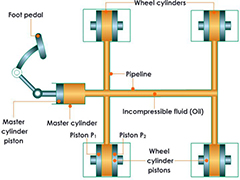

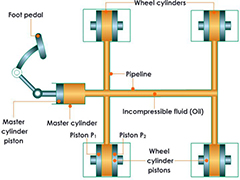

Let's start with a slight overview of what a brake system is. That's simply step on the brake pedal and the car stops! Or at least we hope it does. Perhaps if we understand the system a bit more we can get it to work a bit better. We are going to take a big jump in automotive history and start with a single master cylinder four wheel hydraulic brake system. This is the simplest of the modern brake systems. In its simplest you apply force, your foot stepping down on the pedal, to a cylinder full of fluid. Since fluid is not compressible this means a direct 1 to 1 reaction. 1 pound of force in and one pound out. This fluid flows through the steel lines to your wheel cylinders and pushes the pistons out into contact with the brake shoes and they are pushed out to the drums and you stop. Unfortunately it takes a lot more force than 1 pound to stop. So the first thing we do is make a fulcrum out of the pedal, remember Archimedes saying give me a lever long enough and I can move the world? Well space limits the size of the lever but we start there. Next we discover in our physics class that if we take this fluid and push it from a large space into a small space the pressure goes up again. Open the window all the way and you barely feel the breeze, close it almost all the way and the air coming in is quite noticeable. So now we have stepped the pressure up a good bit between the fulcrum of the pedal and changing the size of the outlet on the master cyl. We did loose volume so we can not move the pistons to far in the wheel cyls. But we really do not have to move them to far and remember this is a sealed system so everything instantly moves. Now at the wheel cyl. we make the whole larger again to get more volume and more movement out to the shoes. Also I want to use all that force I developed in the master cyl completely so I use as large a wheel cyl as I can. So now it should work, I have a pedal giving me a mechanical boost in pressure, I use some physics to get even more hydraulic pressure and use nice big wheel cyls to make it all work. Unfortunately I discover that I can not apply equal pressure to both front and rear brakes. Why not? Well, assume the car weighs the exact same front and rear. As you begin to apply the brakes the weight moves forward and lightens the rear wheels and makes the front get heavier. So now I need more force to stop the front wheels than the rear. This is called brake bias. Get it wrong and things get interesting. Remember the VW rabbit when it first came out? It had so much front bias that the back snapped right around in a panic stop. So now we have to add some bias to the system we can do this by changing the size of the wheel cyls. or adding a specially designed valve called a bias or proportioning valve into the system. So now we finally have it down pat. A pedal that I can push without having a leg built like Hercules and just the right amount of pressure at all the wheels to stop in a straight line. Life is perfect! Well not quite, we discover that we need to think about what we used for the brake material and there is also a problem with drums we are finding out about, and one more thing that is such a major flaw in this system that they outlawed single cyl. systems from production in this country in 1968. The tiniest hole anywhere in the system means no brakes any where!

Brake Tech II

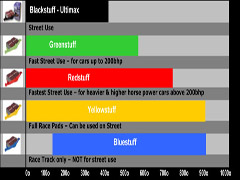

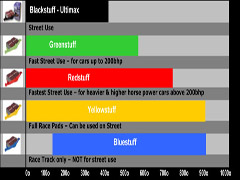

On to linings. The linings are the part of your brake shoe that contacts the drum, or in a disc brake setup the rotor. They are what absorb the energy of stopping your car. That is why brake components get so hot. So we need a lining made up of a material that is strong, slightly flexible, will absorb a lot of energy and does not wear away to fast. At one time asbestos was the answer. We learned that the price in health benefits was not worth it. For some strange reason asbestos brake were referred to as organic brakes. Now we have semi-metallics, full metallics, carbon, ceramic and the list goes on. Your first thought would be I want a nice hard lining. The softer the lining the faster it heats up, the faster it fades and the faster it wears away. But the harder the lining the harder you have to step on the brakes, the longer it takes to build enough heat for the brake material to work properly, the more noise they make and they wear your drums and rotors out faster! For most applications the best stock lining that is available is the best you want to do. It will be a nice blend of everything and suit most needs. If you plan on doing some auto-crossing they will still be very good. Remember most cars built after 1970 have more brakes than go. Now if you are really going to go auto-crossing or racing it is time to move up to a more specific lining. The type of racing you do will determine the type of lining. Also what type of upgrades you can do to the rest of the system. All that energy absorbed by the brakes is released as heat, it needs to go somewhere. The first place is the drums. As they absorb the heat they begin to expand and your brakes need to expand to meet them. Next thing you know you are pumping your brakes to achieve a pedal. The design of the brake system determines how far the brakes can move on a single pedal application. If the brake drums have been over cut the problem gets worse for two reasons; First the drum is bigger because you took metal out when it was resurfaced. Second it has less metal to dissipate the heat so it expand faster and if it is thin enough it will crack. If the linings cannot absorb enough heat and become very, very hot the fluid in the lines will boil and then you have no brakes. Gas compresses unlike fluids so no pedal. In race or extreme conditions special brake lines made of Teflon with stainless steel sheaths and sometimes covered in high temperature silicone are used to help keep the brake fluid cooler, special fluids are used with very high boiling points. For your everyday MGB or MKII Jag or most any car being driven on the roads today, Castrol LMA fluid is what you want to use. It is a DOT4 fluid which is fully compatible with the older DOT3 fluid and DOT4 is what most modern cars are using. Always refer to your owners handbook for final determination of which fluid to use. While you can "mix" DOT3 or DOT4 fluids (but to add DOT3 to DOT4 is going backwards) DOT5 (silicone) and DOT6 (pure race only fluids) can not be mixed with any other type of fluid nor can they be used in many types of systems - read your manuals closely before changing from the specified fluid (all DOT3 specified fluids can and should be upgraded to DOT4 fluids and we recommend Castrol LMA. Girling will only guarantee their product if you use this fluid. If you use a silicone fluid you will void the warranty. Various independent brake cylinder rebuilders will not warranty their work if you use a silicone fluid or some of the "Race Only" Fluids. The problem is not with the silicone per-se but the caring fluid they use. Many times it will not be compatible with the rubber products in your system. It also is not compatible with any non-silicone brake fluid. No matter how slight the contamination. Before you use synthetic fluids check with the manufacturer for compatibility issues. LMA is really all you need and the boiling point is quite high and it can be used quite nicely in many race applications. In normal use you should change your fluid every two years. In pre-war cars I would strongly recommend you have shoes made with modern day linings. Those old web lings were good for stopping tractors! A dual master cyl. is just that. There are two cyls. incorporated in the unit. One works the back and one works the front. Some cars like Volvo split the system left front to right rear. But most are just front and back. There are check valves built into the system so if one of the systems fail you will still have the second system working. Race cars usually have what is called a tandem system where two completely separate master cyls are used linked together with a balance bar so as you step down on the pedal they work in tandem. Take up a lot of room, a bit tricky to set up but are safer in extreme conditions. Disc brakes started showing up in production cars in the 50's. They cost more to make than drum brake systems and in their infancy they had sealing problems. Now almost everything has at least discs on the front axle. In a disc brake the drum is replaced with a rotor and the wheel cyl with a caliper. The caliper holds the brake shoes {now called pads} on each side of the rotor so when you step on the brakes the piston(s) in the caliper push the pads into each side of the rotor thus clamping it. Many advantages to this. First the swept area of the brake is much larger so I get more clamping force and better brakes. I have a larger contact area so I dissipate heat better and a rotor cools better than a drum. As the rotor heats up and expands it actually gets closer to the brake pads so fade is not as big an issue. In fact just the opposite happens sometimes. Though once you get everything super hot you will still boil the fluid and loose brakes. All things being equal a disc brake car will always out stop a drum brake car. But then everything may not be equal as you can learn in the tire and suspension techs. If you plan on altering or upgrading your brake system please consult with a professional, and usually the guy trying to sell it to you is not the person you want to ask. The science that goes into these systems is mind boggling